Industrial DAF Systems

Hydroflux is proud to be Australia’s first water treatment and technology company to achieve Climate Active carbon neutral certification for our entire organization. As part of our climate change mission, we continue to research, develop and invest in sustainable technologies.

Now our journey continues – our main range of water technology and associated chemical products are Climate Active certified as carbon neutral. To read more on our journey, click HERE

There are well over 200 Hydroflux HyDAF systems in operation worldwide being used in a variety of industries in many different applications. Capacities of Hydroflux HyDAF systems can exceed 1000 kL/hr as standalone units and are available in a wide range of configurations.

Hydroflux has installed DAF systems in numerous applications such as:

- Smallgoods

- Meat and poultry

- Prepared foods

- Rendering

- Edible oils and grains

- Plant based manufacturing

- Fruit and vegetables

- Potato and chips

- Beverages

- Bakeries

- Ingredients and spices

- Fish processing

- Mining

- Construction and Groundwater treatment

- Algae and phosphorous removal

- Potable water clarification

- Waste activated sludge thickening and clarification

- Food courts (see GT-DAF pages)

Whether you are looking for a DAF system to treat wastewater, to process waste activated sludge, to be integrated as part of a biological treatment plant, to treat groundwater, remove metals or algae, or one of the many other applications that dissolved air flotation is suitable for, you can be assured that Hydroflux will design and construct a dissolved air flotation system suited specifically to your needs.

Find out more

The HyDAF dissolved air flotation system is a high-quality engineered system designed to efficiently and effectively remove solids from water and wastewater streams.

For every application, the HyDAF is scientifically modelled to ensure that when put into operation, it will meet and exceed all performance and operational expectations.

A HyDAF HD-100 being offloaded at a new food production facility in Sydney

Flotation engineering

A well engineered dissolved air flotation system requires the combination of a robust flotation tank with a suitable solids removal mechanism and an efficient and effective dissolved air production and injection system.

The HyDAF dissolved air flotation system is a superior engineered product designed and manufactured by Hydroflux. The HyDAF system comprises a specially designed inlet mixing system that provides a suitable amount of shear and turbulence where the dissolved air is injected and mixed with the water stream which enhances microbubble attachment and offers improved performance.

The following set of videos show the Hydroflux modelling process with varying dissolved air stream flows and pressures

Hydroflux HyDAF HD35 Whitewater Test

HyDAF HyDAF HD35 Air v Streamlines – Cutaway

Hydroflux – HyDAF HD35 Whitewater Test – ISO

Float removal

Maximising the dry solids concentration in DAF float is an important feature to most operators as it means less volume of sludge is generated making it more cost effective to dewater or dispose of.

The HyDAF system features a robust 6 sprocket mechanical scraper system that scrapes the float to the inlet end of the DAF which improves overall solids capture whilst the scraper always maintains contact with the discharge beach to maximise the dry solids content in the sludge. The scraper components are designed with longevity and maintenance in mind. The chain only requires the occasional application of grease, which can be optionally automated, and easily adjusted from outside the DAF tank when necessary.

The HyDAF generates float with very high dry solids concentration minimising the volume to be dewatered or disposed of.

The scraper design is available with several options including:

- Mild steel or stainless steel sprockets and chains

- Various scraper materials to suit the chemical properties of the float

- Finger blades to further thicken the sludge

- Automatic lubrication systems

- Automated scraper and sludge hopper washing systems

Dissolved air

Ensuring that the correct amount of dissolved air is injected into the DAF inlet is essential for the performance of the system.

Hydroflux utilises a proprietary proven engineering design tool to ensure that the dissolved air system is appropriately sized for every application. The engineering tool takes into account the influent flow rate, solids load, temperature and operating pressure.

The Hydroflux dissolved air production system is designed for each application to suit the conditions

Features of the recycle system include:

- Stainless steel saturation vessel that contains no internal instruments or components

- Non-blocking design with stainless steel closed impeller high efficiency pump and self-cleaning pressure reduction valve

- Integrated air control panel enabling accurate adjustment of air flow

- Proven design in hundreds of installations

Settled sludge removal

Hydroflux has three flotation tank configurations available to suit all types of influent streams.

The configuration of the base of the HyDAF depends on the flow and the amount of heavy solids in the wastewater stream

The standard designs include:

HD Range: effective when minimal settled solids are expected, and the entire DAF can be easily drained when required.

HD-V Range: designed for wastewater streams with a high probability of sedimentation. This unit is fitted with steep sloping sides and a screw conveyor that automatically extracts settled solids.

HD-S range: designed for large DAF systems with multiple hoopers to facilitate automated withdrawal of solids on a regular basis.

Capacities

The Hydroflux DAF systems are available in a range of convenient sizes to suit any application. From the smallest HyDAF HD10 to the HyDAF HD250V, we can treat flows up to 5 ML/day in a single standalone unit. For larger applications found in mining, the pulp and paper industry and some food and beverage sites, Hydroflux works with our partner Flootech and can offers DAF systems capable of treating 1 ML/hr.

All DAF systems are selected based on the flow rate to be treated and the solids load. Please contact Hydroflux for sizing details.

From the smallest HyDAF HD 10 capable of treating from 10 k/hr to the HyDAF HD250 which can process in excess of 300 kL/hr

“What is the capacity of the HyDAF dissolved air flotation systems?”

The HD range of HyDAF dissolved air flotation systems are designed for industrial applications where high solids loads are usually experienced. We have standard sizes and configurations of flotation tanks but in each case, we match this with the most suitable model of dissolved air recycle system to suit the specific wastewater characteristics.

“What is the HyDAF HD-V range?”

This is a HyDAF system designed with steep sloping sides and an auger in the base. It is specifically used when the wastewater in question contains a reasonable proportion of settleable solids such as grit from a meat processing plant for example.

A Hydroflux HyDAF HD-100V installed at a meat processing plant in WA

“What is the FlooDAF® range?”

FlooDAF is designed by Flootech which is one of Hydroflux’s many international exclusive partners. The FlooDAF® is an economical range of DAF systems for large flows up to 1000 m3/hr.

“Is the HyDAF dissolved air flotation suitable shopping centers and food courts?”

Yes, but we have designed a GT range of dissolved air flotation systems specifically suited for treatment of wastewater from shopping centers and foods courts. Please click here to be directed to the GT-DAF pages.

A FlooDAF designed to treat over 500 kL/hr as a single unit

“Can the HyDAF dissolved air flotation system handle variable load and flows?”

This depends. In applications where chemicals are not being used, the HyDAF dissolved air flotation system can operate and effectively treat wastewater at any flow and solids load up to its design capacity. If chemicals are being dosed, then variations in flow and solids load will adversely affect the chemical process. In these cases, the installation of a balance tank upstream of the HyDAF dissolved air flotation and a constant feed rate is recommended.

“Do I need to dose chemicals into the wastewater?”

Dosing of chemicals into the wastewater upstream of the HyDAF dissolved air flotation system will improve the performance of the system. Whether it is necessary to dose chemicals depends on the treated water quality that is required. Hydroflux can tailor specific chemical programs to ensure performance requirements are met economically whilst minimising the amount of sludge that will be generated. For more information on our chemical division, please click here to visit the Hydroflux Utilities web site

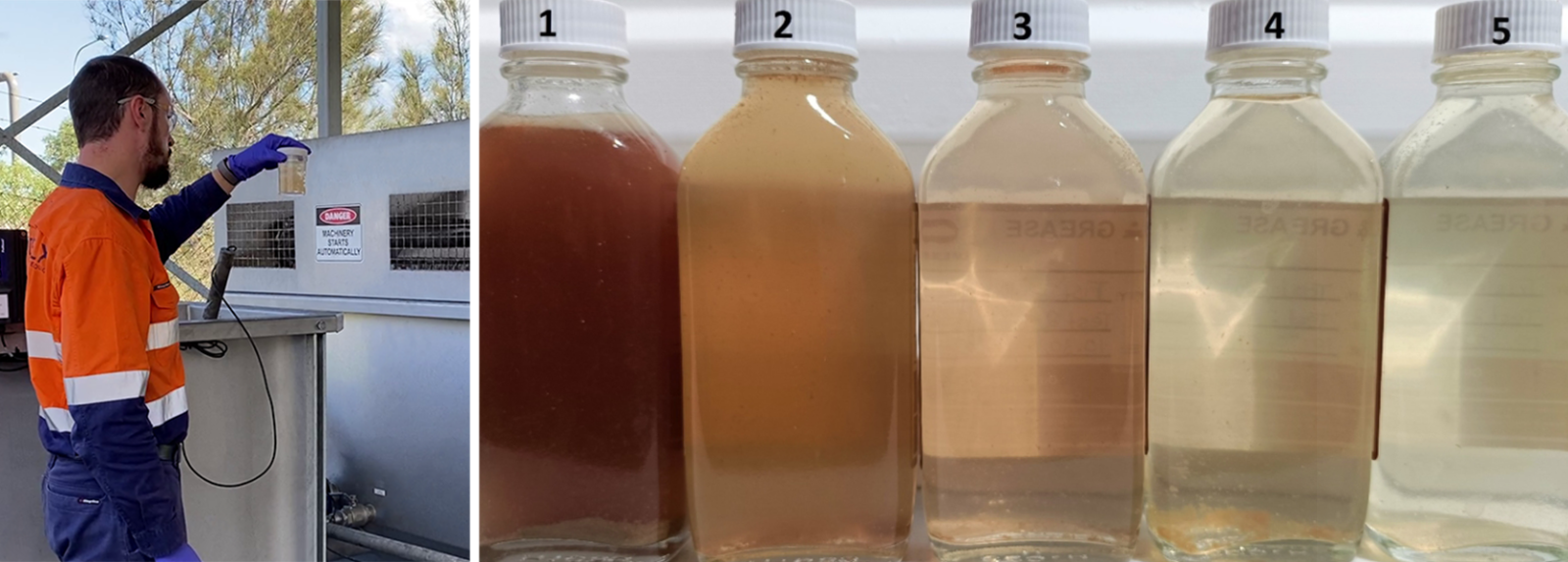

Hydroflux will determine the most suitable chemical program for every application

D&C of a primary and MBBR treatment plant at a food processing plant in QLD comprising two HyDAF HD-10 units

D&C of a primary and MBBR treatment plant at a food processing plant in QLD comprising two HyDAF HD-10 units

D&C of a primary and MBBR treatment plant at a food processing plant in NSW comprising two HyDAF HD-35 units

D&C of a primary and MBBR treatment plant at a food processing plant in NSW comprising two HyDAF HD-35 units

The DAF system is just one process component in complete water or wastewater treatment plant and is usually supported by a range of ancillary process operations to condition the influent, handle the sludge generated, or provide further treatment or recycling. Hydroflux has the skills and expertise to conduct any design and construct project incorporating a DAF system.

Hydroflux employs qualified civil, mechanical, chemical and electrical engineers plus a team of experienced project managers, site supervisors, commissioning engineers and service technicians based in offices throughout Australia providing a local presence throughout the duration of the project.

All projects are conducted under externally approved occupational health and safety, and environmental management systems.

Hydroflux design and construct a complete wastewater treatment system involving flotation technology.

Hydroflux is Australia’s first Water-tech company to achieve Climate Active certifications which means by engaging with Hydroflux you are supporting positive and verified action on climate change.

Construction of a turnkey wastewater treatment plant at a new food production facility in SA

The Utilities division provides the link to integrating the Hydroflux® businesses by providing a comprehensive support network for customers throughout Australia.

Hydroflux Utilities provides virtually any form of wastewater management programs including:

Chemical optimisation

Hydroflux has a comprehensive range of coagulants and flocculants suitable for conditioning wastewater or sludge. The most appropriate chemical program will be determined before commissioning based on experience, or test work if possible, and long-term cost-effective chemical supply contracts can be arranged.

Preventative maintenance and service

Our engineers and technicians will discuss service and maintenance programs with you during construction of the wastewater treatment plant so that you can be ensured that the system will perform consistently from day 1. There are many types of programs available from routine preventative maintenance, periodic service and overhauls, to complete plant operation. Our technicians are available 24/7 to attend to unforeseen breakdowns.